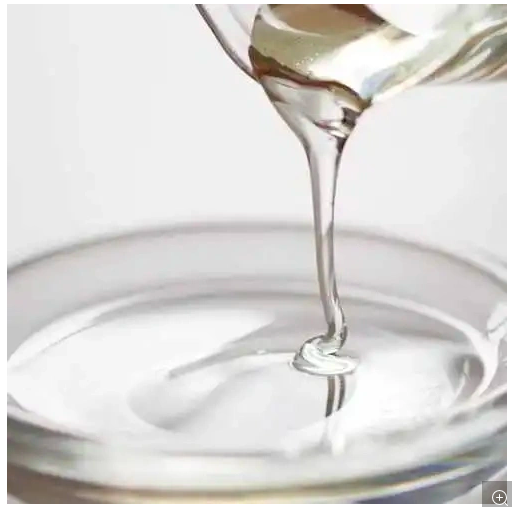

Vat photopolymerization, musamman Laser stereolithography ko SL/SLA, shine farkon fasahar bugu na 3D akan kasuwa. Chuck Hull ya ƙirƙira shi a cikin 1984, ya ƙirƙira shi a cikin 1986, kuma ya kafa 3D Systems. Tsarin yana amfani da katako na Laser don yin polymerize kayan monomer mai hoto a cikin vat. Yadudduka na hotopolymerized (masu warkewa) suna manne da farantin gini wanda ke motsawa sama ko ƙasa dangane da kayan aikin, yana barin jeri-jeri su yi. Tsarin SLA kuma na iya samar da ƙananan ƙananan sassa na musamman ta amfani da ƙaramin diamita na katako na Laser, a cikin tsarin da aka sani da micro SLA ko µSLA. Hakanan za su iya samar da manyan sassa ta amfani da diamita mafi girma da tsayin lokacin samarwa, a cikin ƙididdige ƙididdigewa sama da mita cubic biyu.

Mawallafin SLA-1 Stereolithography (SLA), firinta na 3D na kasuwanci na farko, 3D Systems ya gabatar da shi a cikin 1987.

Akwai bambance-bambancen fasahar vat photopolymerization da yawa da ake samu a yau. Na farko da ya fito bayan SLA shine DLP (Digital Light Processing), wanda Texas Instruments ya haɓaka kuma ya kawo kasuwa a cikin 1987. Maimakon yin amfani da katako na laser don photopolymerization, fasahar DLP tana amfani da na'urar hasken dijital (mai kama da na'urar majigi na TV). Wannan yana sa shi sauri fiye da SLA, saboda yana iya ɗaukar hoto gaba ɗaya na abu a lokaci ɗaya (wanda ake magana da shi azaman "tsari"). Koyaya, ingancin sassan ya dogara da ƙudurin majigi kuma yana raguwa yayin da girma ya ƙaru.

Kamar extrusion na kayan abu, stereolithography ya zama mafi sauƙi tare da samuwa na tsarin ƙananan farashi. Tsarukan masu rahusa na farko sun dogara ne akan ainihin tsarin SLA da DLP. Koyaya, a cikin 'yan shekarun nan, wani sabon ƙarni na matsananci-ƙananan farashi, ƙaƙƙarfan tsarin da ya dogara da tushen hasken LED/LCD ya fito. Juyin halitta na gaba na vat photopolymerization an san shi da "ci gaba" ko "marasa Layer" photopolymerization, wanda yawanci ya dogara ne akan gine-gine na DLP. Waɗannan matakai suna amfani da membrane, yawanci oxygen, don ba da damar saurin samarwa da sauri. An fara rajistar patent na irin wannan nau'in stereolithography a cikin 2006 ta EnvisionTEC, kamfanin DLP wanda tun daga lokacin aka sake masa suna a matsayin ETEC, bayan samun sa ta hanyar Desktop Metal. Koyaya, Carbon, wani kamfani na Silicon Valley, shine farkon wanda ya fara tallata wannan fasaha a cikin 2016 kuma tun daga lokacin ya kafa kansa a matsayin jagora a kasuwa. Fasahar Carbon, wacce aka fi sani da DLS (Digital Light Synthesis), tana ba da ƙimar yawan aiki mai girma da kuma ikon samar da sassa tare da kayan ɗorewa masu ɗorewa, haɗa thermosets da photopolymers. Sauran kamfanoni, irin su 3D Systems (Hoto na 4), Origin (yanzu wani ɓangare na Stratasys), LuxCreo, Carima, da sauransu, sun kuma gabatar da irin wannan fasaha a kasuwa.

Lokacin aikawa: Maris 29-2025